System Specifications

Load Centres

Cirrus 100 Series chain is comprised of alternating vertical load bearings and horizontal guide bearings. Load bearings are located on 6-inch centres, thereby allowing loads to be arranged on any multiples of 6-inches. Load bearings include a hanging pendant from which loads are attached.

Load Capacity

The maximum load that can be suspended from a single load point on the chain is 50-pounds. Loads of 100-pounds can be suspended when using a load bar that connects between two chain pendants.

Chain Pull

Chain pull is the force required to overcome the rolling resistance of the conveyor chain. The chain pull on a given system is proportional to the individual load weights, load centres, number of elevation changes, quantity of horizontal curves and overall environment that the system operates in. The Cirrus C-100 system chain pull averages 2.5% of the sum of the moving load. Long systems in harsh environments will have a much higher coefficient of friction. Maximum chain pull for a single caterpillar drive is 600-pounds.

Contact Cirrus for chain pull calculations that relate to your system.

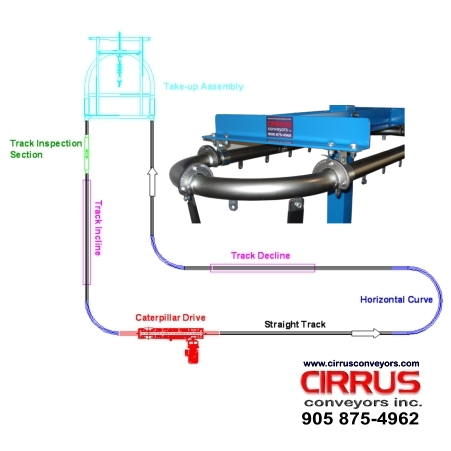

Typical System Components

Chain & Attachments

Series 100 conveyor chain is constructed from bearings connected with a formed clevis and clevis pin. A set of two vertical load bearings carry loads and roll within the bottom portion of the track. Vertical load bearings are captured by a 'T' shaped pendant with a 5/16" diameter hole on the bottom from which loads can be attached. Horizontal bearings guide the chain horizontally within straight track and horizontal curved track sections.

Chain is shipped in 10-foot coils complete with connecting pin.

A wide range of attachments are available that hook into the load pendant from which product loads can be carried. A variety of indexing hooks and swivel rotator bearings are available to allow loads to index at 90-degree intervals or rotate freely. Use the sanitary tray attachment that connects directly to the chain to keep your products free from dust and grime.

For loads that exceed the 50-pound hanging limit, a load bar can be used to distribute the load between two load bearings, raising the limit to 100-pounds.

Track & Accessories

Straight track is roll formed from carbon steel with a wall thickness of 1/8". Track lengths come with a 3-hole flange on both ends, allowing for a bolted construction. Loose flanges are available for track lengths shorter than ten feet. Track comes zinc plated. Standard lengths are shipped in 10-foot segments. Stainless steel track is also available, providing long life in challenging environments such as parts washers.

Each system will contain at least one chain installation gate which also serves as an inspection port. This straight section of track has a removable top cover, allowing access to the chain. The overall length of an inspection section is 9 3/4-inches.

Oven expansion joints are required in long straight runs of track to compensate for thermal expansion in ovens.

Horizontal Track Curves

Horizontal curves are formed from straight track sections and heat treated after forming. Radii available range from 9-inch to 36-inch centreline radius. The most common are 24-inch centreline radius. Curves are typically shipped in segments of 15-degree, 30, 45 and 90-degrees.

Vertical Track Curves

Vertical track curves are formed from straight track sections and heat treated after forming. In order to complete a change in elevation, two types of vertical curves are required. A lower vertical curve leads the chain from level to an incline and a top vertical curve takes the chain from an incline back to a horizontal position. Straight track between the vertical curves can be added to increase the overall incline or decline of the elevation change.

Three radii of vertical curves are available: 24-inch, 36-inch and 48-inch centreline radius. The most common are 24-inch centreline radius. Curves are typically shipped in segments of 15-degree, 30, 45, 90 and 180-degrees.