System Specifications

Load Centres

Load carrying trolleys mount to the chain through centre links which are located on 8-inch pitches. Therefore, loads can be carried on any multiple of 8-inch centres, providing trolleys are installed on the same desired load pitch.

Load Capacity

The maximum load that can be suspended from a single trolley pair is 400-pounds. Loads of 800-pounds can be suspended when using a load bar that connects between 2-trolleys.

Chain Pull

Chain pull is the force required to overcome the rolling resistance of the conveyor chain. The chain pull on a given system is proportional to the individual load weights, load centres, quantity of elevation changes, quantity of horizontal curves and overall environment that the system operates in. An average system chain pull will typically range between 2% and 5% of the sum of the moving load. Maximum chain pull for a single caterpillar drive is 3000-pounds.

Contact Cirrus for chain pull calculations that relate to your system.

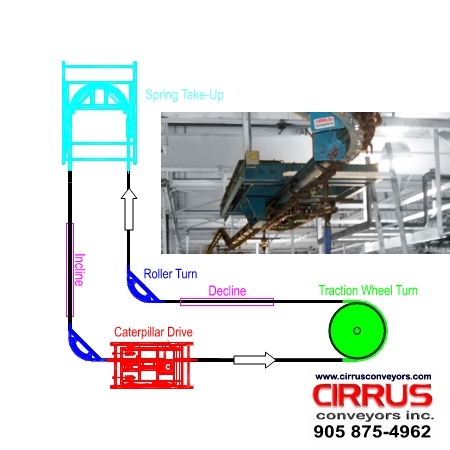

Typical System Components

Chain & Attachments

Cirrus X458 chain is constructed from forged links and pins that allow for chain assembly without any tools. A pair of outside links capture a centre link, held together by a forged chain pin. The centre and outside links alternate on 4-inch centres.

Trolleys consist of 2-individual side arms, each with a bearing. When paired together and inserted in a centre chain link, the trolley pair carries the conveyor chain and may carry a load. In cases were loads are on large centres, intermediate trolleys are still required to carry the conveyor chain.

The maximum distance that trolleys can be spaced on a system is proportional to the radius of horizontal and vertical track curves and the length of the caterpillar drive. Ask Cirrus to determine the trolley centres for your specific system layout.

A wide range of attachments are available for suspending loads. The most common is the H attachment, consisting of two formed steel plates from which hooks and other attachments can hang. A variety of indexing hooks and swivel rotator bearings are available to allow loads to index at 90-degree intervals or rotate freely.

If cleanliness is critical in your operation, sanitary hooks can be attached to the trolleys. These hooks loop around one side of the I-beam track to allow a drip tray to be installed directly under the chain and track.

For loads that exceed the 400-pound per trolley hanging limit, a load bar can be used to distribute the load between two trolleys, raising the limit to 500-pounds.

Track & Accessories

4-Inch I-beam straight track provides a surface for the conveyor trolleys to run upon. Track is finish painted medium blue (other colours available) and is provided in 20-foot lengths. Stainless steel track is also available, providing long life in challenging environments such as parts washers.

Oven expansion joints are required in long straight runs of track to compensate for thermal expansion in ovens.

Anti-runaway and anti-backup assemblies provide added safety on track elevation changes in the event that a chain breakage takes place.

Roller Turn Horizontal Curves

Roller turns are used to guide the chain and trolleys through horizontal track curves. Individual bearings are centred vertically on the chain centreline to guide it through the turn. A steel frame houses the rolled track and roller nest.

Roller turns come in a wide range in radii and degree. The most common are 24-inch centreline radius. Curves are typically shipped in segments of 30-degree, 45, 60, 90 and 180-degrees.

Traction Wheel Horizontal Curves

Like roller turns, traction wheels are also used to guide the chain and trolleys through horizontal track curves. Traction wheels consist of a single large disc (solid plate or spokes) with a central hub and bearing assembly from which the wheel hangs. A wheel rim is centred vertically on the chain centreline to guide it through the turn. A steel frame houses the rolled track and traction wheel.

Traction wheel hubs are available with bearings or bushings depending on the where they will be used. Cure ovens, commonly found in paint finishing systems, operate at temperatures too great for standard bearings. In these circumstances hubs containing a graphite bushing are provided which run on a smooth polished shaft. Traction wheels operating in ambient temperatures use standard bearing type hubs and are lubricated with grease.

Traction wheel turns come in a wide range of diameters and degrees. The most common are 48-inch diameter. Curves are typically shipped in segments of 45-degree, 60, 90 and 180-degrees.