System Specifications

Free Trolley Load Centres

Using a typical free trolley set (leading and trailing trolley) with load bar, the minimum load bar accumulation centres are approximately 15-inches. For very small loads a combination trolley without load bar can be used, offering accumulation centres of approximately 8-inches.

Pusher Dog Centres

Pusher dogs, consisting of a 4-wheeled chain link and cast dog, are installed in place of chain load bearings on any multiple of the minimum 8-1/8" centres.

Load Capacity

The maximum load that can be suspended from a 2-trolley load bar is 1,500 pounds. A single combination trolley can carry a maximum load of 750-pounds.

Chain Pull

Chain pull is the force required to overcome the rolling resistance of the conveyor chain. The chain pull on a given system is proportional to the individual load weights, load centres, quantity of elevation changes, quantity of horizontal curves and overall environment that the system operates in. An average system chain pull will typically range between 1.5% and 5% of the sum of the moving load. Maximum chain pull for a single caterpillar drive is 750-pounds.

Contact Cirrus for chain pull calculations that relate to your system.

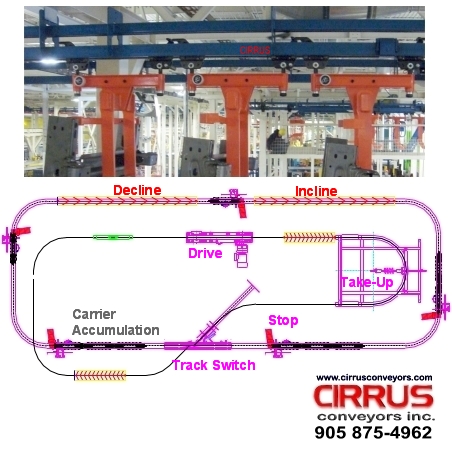

Typical System Components

Power Rail Components

See our Series 800 Conveyor System page for details on the power components of Cirrus 800 Power & Free.

Pusher Dogs

Pusher dogs provide the connection between the powered chain and the free rolling trolley / load bar assembly that carries product loads. Pusher dogs, consist of a 4-wheeled chain link and cast pivoting dog installed in place of chain load bearings on any multiple of 8-1/8" centres. The claw dog is attached to the 4-wheel trolley body with a clevis pin to allow for dog replacement without having to break the conveyor chain.

P&F Track

Straight track is comprised of roll formed 5/32" wall enclosed track positioned over a pair of 3-inch channel tracks, all tied together with flame cut track yokes.

The overall track dimension, measured from the top of the track yoke to the bottom of the 3-inch channels is 11-inches. The overall width including track yoke measures 9 1/16" inches. Track is finish painted medium blue and is available in 10 and 20-foot lengths. Stainless steel track is also available, providing long life in challenging environments such as parts washers.

Each system will contain at least one chain installation gate which may also serve as an inspection port for the power chain. This straight section of track is hinged on one side, allowing access to the chain. There is also an inspection gate that hinges on the top to provide access to the chain. The overall length of an inspection section is 27-inches.

Each system will also contain at least one free trolley installation gate. This gate allows open access to the 3-inch channel track where free trolleys can be installed or removed from the system.

Oven expansion joints are required in long straight runs of track to compensate for thermal expansion in ovens.

P&F Horizontal Track Curves

Horizontal curves are formed from straight enclosed track sections and roll formed 3-inch channel tracks, all tied together with flame cut track yokes. Common radii available include 24, 36 and and 48-inch centreline radius. The most common are 24-inch centreline radius. Curves are typically shipped in segments of 30-degree, 45, 60, 90 and 180-degrees.

P&F Vertical Track Curves

Vertical track curves are formed from straight enclosed track sections and roll formed 3-inch channel tracks, all tied together with flame cut track yokes. In order to complete a change in elevation, two types of vertical curves are required. A lower vertical curve leads the chain from level to an incline and a top vertical curve takes the chain from an incline back to a horizontal position. Straight track situated between the vertical curves can be added to increase the overall incline or decline of the elevation change.

Track elevation changes use tight bite track to ensure that loads can never disengage from the claw dogs. Standard straight track has a drop of 6-inches (measured from the bottom of the power track to the bottom of the free track). Tight bite track arranges the power track and free tracks closer together (5-1/2" on declines, 5-1/8" on inclines) which results in no available space for the claw dog to pivot clear of the leading trolley. Transition sections of track are used leading into and exiting elevation changes to match the tight bite track drop dimension.

Two radii of vertical curves are available - 36-inch chain centreline radius and 48-inch chain radius. The most common are 36-inch centreline radius. Curves are typically shipped in segments of 30-degree, and 45-degrees.

P&F Accumulating Trolleys

Free trolleys, usually in combination with a load bar, carry product loads. Trolleys are manufactured from steel castings that come with axles, four load bearings and two guide rollers.

Lead trolleys are positioned at the front of a load bar in the direction of travel. Pusher dogs, mounted on the conveyor chain, engage on the lead trolleys to propel loads throughout the system. The method in which the pusher dog engage lead trolleys also ensures that loads remained captured when transitioning track declines through changes of elevation.